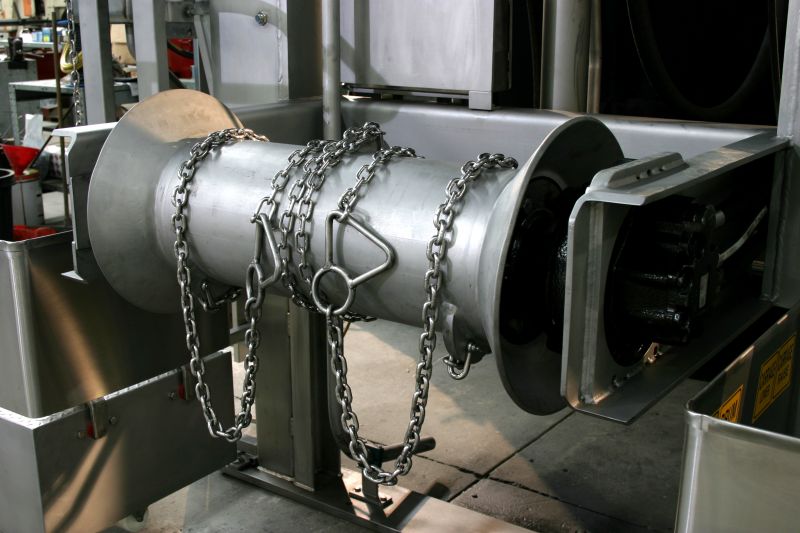

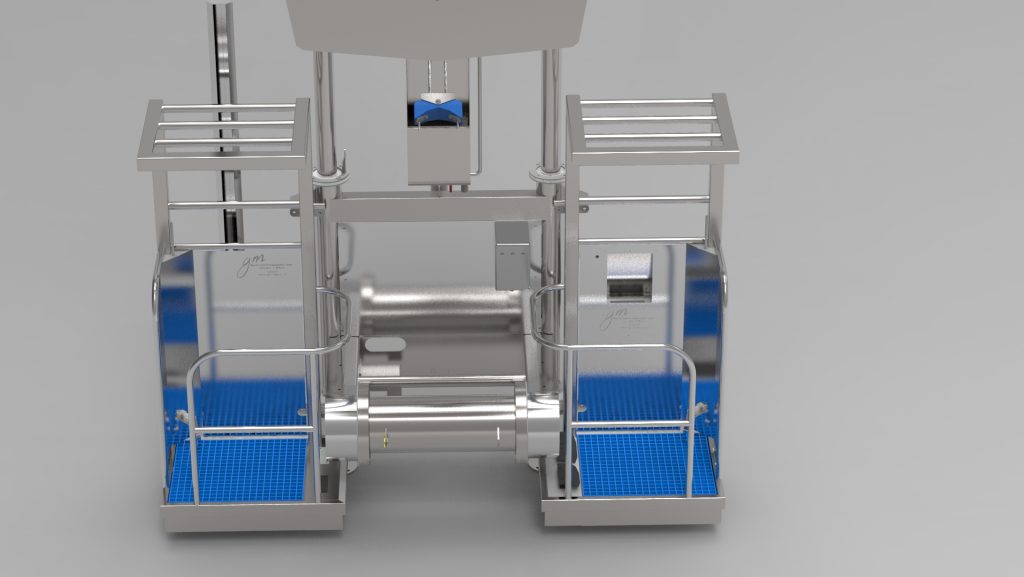

A Cattle Dehider or Hide Puller Machine is a specialized piece of equipment used in the meat processing and slaughterhouse industry. Designed to remove the hide from cattle carcasses efficiently and hygienically, this machine plays a crucial role in modern slaughterhouse operations. The machine uses either hydraulic or pneumatic power to grip and pull the hide with precision, ensuring minimal damage to the hide and the meat underneath. Its robust construction ensures durability, while safety features protect operators during the dehiding process.

Application of Use of Hide Puller for Slaughterhouse

The Cattle Dehider or Hide Puller Machine is commonly used in industrial-scale slaughterhouses for:

- Efficiently removing cattle hides without manual labor.

- Ensuring clean and hygienic meat processing by minimizing contamination.

- Reducing processing time and increasing throughput.

- Preserving the quality of hides for leather production.

- Handling various cattle sizes through adjustable settings and grip mechanisms.

How It Operates the Hide Puller for Slaughterhouse

The operation of a Cattle Dehider or Hide Puller Machine involves the following steps:

- The cattle carcass is positioned on the processing line.

- The machine’s gripping mechanism securely holds the hide.

- Hydraulic or pneumatic power pulls the hide from the carcass in a controlled motion.

- The removed hide is collected for further processing or disposal.

The machine ensures a seamless and safe operation with controls that allow the operator to monitor the process in real-time.

Maintenance Guide of Hide Puller Slaughterhouse

Proper maintenance of the Cattle Dehider or Hide Puller Machine is essential for optimal performance and longevity:

- Daily Cleaning: Wash all parts that come into contact with the hide or carcass to prevent contamination.

- Lubrication: Regularly lubricate moving parts to reduce wear and ensure smooth operation.

- Inspection: Check hydraulic or pneumatic systems for leaks or damage.

- Blade Maintenance: Replace worn or damaged blades to ensure efficient hide removal.

- Routine Servicing: Schedule regular professional servicing to keep the machine running efficiently.

Popular Brands of Hide Puller Slaughterhouse

Several manufacturers produce high-quality Cattle Dehider or Hide Puller Machines for slaughterhouses. Some of the most reputable brands include:

- Jarvis Products: Known for their innovative designs and durable machinery.

- Frey: Offers customizable solutions for various slaughterhouse needs.

- Kentmaster: A trusted name in the meat processing industry with reliable and efficient machines.

- BAADER: Specializes in high-capacity machines for industrial-scale operations.

Who are using this in Bangladesh of Hide Puller for Slaughterhouse

1. Bengal Meat Processing Industries Ltd.

- Website: www.bengalmeat.com

- One of the leading meat processing companies in Bangladesh, utilizing advanced machinery like hide pullers for efficient cattle processing.

2. Pran-RFL Group (Meat Processing Division)

- Website: www.pranfoods.net

- Operates facilities for meat processing and exports, relying on modern equipment for cattle dehiding.

3. Dutch Dairy Ltd.

- Website: www.dutchdairybd.com

- Engaged in livestock processing for meat production, ensuring compliance with international hygiene and operational standards.

4. Dhaka South City Corporation Project (Hazaribagh and Kaptan Bazar)

- Website: www.dscc.gov.bd

- Cattle slaughterhouses under city corporation projects in Hazaribagh and Kaptan Bazar utilize hide puller machines to modernize slaughtering processes and meet urban demand.

5. Dhaka Tannery Industrial Estate

- Website: www.lmb.gov.bd (Bangladesh Leather Sector Authority)

- Leather processing plants in the tannery hub depend on hides obtained using efficient dehiding equipment for quality leather production.

6. Various Export-Oriented Meat Processing Units

- Many export-oriented businesses use automated equipment like hide pullers to meet international quality and hygiene standards.

These organizations rely on Cattle Dehider or Hide Puller Machines to optimize productivity, ensure hygiene, and meet global industry requirements.

The capacity range of Cattle Dehider or Hide Puller Machines can vary based on the model and manufacturer. Typically, these machines are categorized as follows:

- Micro-Scale Units:

- Ideal for small butcher shops or manual operations.

- Capacity: 5–10 cattle per hour.

- Small-Scale Units:

- Suitable for small slaughterhouses or low-volume processing facilities.

- Capacity: 15–30 cattle per hour.

- Medium-Scale Units:

- Designed for mid-sized facilities with moderate operational demands.

- Capacity: 30–50 cattle per hour.

- Large-Scale or Industrial Units:

- Built for large slaughterhouses and export-oriented facilities.

- Capacity: 50–100+ cattle per hour.

Applications for Micro-Scale Units of Hide Puller Slaughterhouse

- Small rural slaughterhouses.

- Local meat processing for village or district markets.

- Training or pilot projects for new facilities.

Manufacturers provide these smaller units to address specific needs for low-cost, compact solutions.

The Cattle Dehider or Hide Puller Machine is used during the hide removal step in the slaughtering process of cattle. This step typically occurs after the following key processes:

Step-by-Step Process Leading to Dehiding

- Stunning: The cattle are stunned to ensure humane slaughter.

- Bleeding: Blood is drained from the animal to meet hygienic and halal requirements.

- Legging and Head Removal: The head and lower parts of the legs are removed to facilitate dehiding.

Dehiding Process (Where the Machine Is Used)

- The Dehider or Hide Puller Machine is employed to carefully strip the hide from the carcass.

- The process is often automated or semi-automated, ensuring minimal damage to the hide (valuable as a by-product) and preserving the integrity of the carcass.

- The machine uses either hydraulic or pneumatic mechanisms to efficiently pull the hide in one clean motion.

Post-Dehiding Steps

- Carcass Splitting: The carcass is split for further processing.

- Evisceration: Internal organs are removed.

- Washing and Inspection: The carcass is cleaned and inspected for quality.

The Cattle Dehider or Hide Puller Machine is a critical component in modern slaughterhouses, ensuring efficiency, hygiene, and quality during the hide removal stage.

Future of Meat Processing Industries in Bangladesh as using Hide Puller for Slaughterhouse

The meat processing industry in Bangladesh is poised for significant growth and transformation in the coming years due to evolving consumer preferences, rising demand, and technological advancements. Below are some key trends and developments shaping the future of this sector:

1. Rising Domestic Demand

- Urbanization and Middle-Class Growth: Increasing urbanization and a growing middle-class population have led to higher demand for hygienic and processed meat products.

- Changing Dietary Patterns: Consumers are shifting towards protein-rich diets, increasing the consumption of beef, mutton, and poultry.

- Convenience Foods: Ready-to-cook and processed meat products are becoming more popular among busy urban households.

2. Export Potential

- Global Halal Market: Bangladesh is well-positioned to tap into the global halal meat market, especially in Middle Eastern and Southeast Asian countries.

- Quality Assurance: Improvements in compliance with international standards such as HACCP, ISO, and halal certification will boost export capabilities.

- Leather By-Products: Growth in the leather sector further supports the export of processed meat and animal by-products.

3. Technological Advancements

- Automation: Introduction of advanced machinery, such as automated slaughter lines and robotics, will improve efficiency and hygiene in processing plants.

- Refrigeration and Cold Chain: Investments in cold storage and transportation will help preserve meat quality, reducing wastage.

- Traceability Systems: Adoption of digital systems for tracking meat quality and safety from farm to fork.

4. Government Initiatives

- Policies and Subsidies: The government is supporting meat processing industries through favorable policies, loans, and subsidies to modernize facilities.

- Public-Private Partnerships (PPP): Collaborations between government bodies and private companies are expected to enhance industry infrastructure.

- Zoning and Industrial Parks: Dedicated zones for slaughterhouses and meat processing plants are being developed to meet demand and address environmental concerns.

5. Sustainable Practices

- Organic and Grass-Fed Meat: Growing interest in organic, free-range, and grass-fed meat to cater to health-conscious consumers.

- Waste Management: Technologies for processing waste into by-products like animal feed, fertilizers, and bio-energy are gaining traction.

- Eco-Friendly Practices: Implementation of green practices to reduce the environmental impact of slaughterhouses and processing plants.

6. Investment Opportunities

- Foreign Investments: Growing interest from international companies to invest in Bangladesh’s meat processing sector due to its potential for expansion.

- Local Entrepreneurs: More local businesses are entering the market, diversifying meat products and packaging to meet demand.

Challenges to Address

- Infrastructure Gaps: The lack of modernized slaughterhouses and cold chain infrastructure.

- Regulatory Compliance: Ensuring strict adherence to hygiene, safety, and halal standards.

- Training and Workforce Development: Upskilling workers for efficient operation of advanced machinery.

The meat processing industry in Bangladesh is set for a transformative journey, driven by domestic demand, export potential, and technological innovation. By addressing infrastructure gaps and investing in sustainability, the sector can achieve long-term growth and establish itself as a key player in the global meat market.

Immenso.com.bd and Mycart.com.bd are renowned companies in Bangladesh, recognized as leading suppliers of meat and slaughterhouse machinery. They provide cutting-edge solutions to meet the growing demand for efficient and hygienic meat processing in the country.

One of the prominent products offered by Immenso.com.bd is the Dehider Puller (WFA-FC-D05), a high-performance cow skinning machine tailored for cattle slaughterhouses. This machine ensures precision and efficiency in the dehiding process, reducing time and labor while maintaining strict hygiene standards.

For more details, visit the product page on Immenso’s official website: Dehider Puller (WFA-FC-D05) – Slaughterhouse Equipment.

By offering advanced machinery like the Dehider Puller, Immenso and Mycart are instrumental in driving innovation in the meat processing industry of Bangladesh.