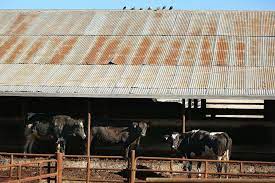

The duration of time and location where cattle are housed between arrival at an abattoir and slaughter is termed ‘lairage’ as Cattle Lairage.

A cattle lairage is a holding area where livestock, primarily cattle, are kept before slaughter. It’s a critical component of any slaughterhouse, ensuring the animals are handled humanely and efficiently.

Infrastructure and Design for Cattle Lairage

Key Considerations:

- Size and Capacity: The size of the lairage should be sufficient to accommodate the expected number of animals without overcrowding.

- Ventilation: Adequate ventilation is essential to maintain air quality and prevent heat stress.

- Lighting: Proper lighting can reduce stress on the animals and improve visibility for workers.

- Flooring: The flooring should be non-slip, easy to clean, and comfortable for the animals.

- Water Supply: Clean, fresh water should be readily available.

- Feed and Trough: Adequate feeding and watering troughs should be provided.

Space Requirements:

The required space per animal can vary based on factors like breed, size, and local regulations. However, a general guideline is to allocate around 10-12 square feet per medium-sized cattle.

Facilities and Equipment for Cattle Lairage

- Holding Pens: Separate pens for different groups of animals to minimize stress and prevent disease transmission.

- Loading Ramp: A ramp for loading and unloading animals.

- Corridor: A narrow passageway to guide animals to the slaughterhouse.

- Resting Area: A quiet area for animals to rest before slaughter.

Pre-Slaughter Resting Time

The ideal resting period before slaughter can vary, but a general recommendation is 12-24 hours. This allows the animals to recover from transportation stress and ensures a calmer and more humane slaughter process.

Technical Considerations

- Stress Reduction: Minimize noise, sudden movements, and overcrowding to reduce stress on the animals.

- Temperature Control: Maintain a comfortable temperature to prevent heat stress or hypothermia.

- Hygiene: Regularly clean and disinfect the lairage to prevent the spread of diseases.

- Biosecurity: Implement strict biosecurity measures to protect the animals from disease outbreaks.

By adhering to these guidelines, slaughterhouses can ensure the humane treatment of animals and improve the overall efficiency and quality of their operations.

Recent research from Meat & Livestock Australia (MLA) sheds light on the benefits of short duration lairage (SDL) for grainfed cattle. Lairage refers to the time and location animals are housed between arriving at a slaughterhouse and slaughter. Traditionally, this period can range from 2-36 hours, often involving an overnight stay.

The MLA study, involving over 2,200 cattle, compared three lairage durations:

- Short (4 hours)

- Mid (16.5 hours)

- Long (26.5 hours)

Key Findings:

- Increased profitability: SDL resulted in a significant 7.4kg to 6.2kg increase in hot standard carcase weight (HSCW) compared to mid and long lairage, respectively. This translates to $40-$48 per head in additional revenue (assuming $6.50/kg HSCW price).

- Improved animal welfare: Shorter lairage led to better hydration (lower packed cell volumes) and higher liver glycogen content, indicating improved energy stores.

- Maintained food safety: No negative effects on meat quality or food safety parameters were observed with SDL.

- Environmental benefits: SDL may contribute to lower emissions intensity per carcase (estimated 1.2% reduction in CO2-e).

Opportunities and Considerations:

- Current adoption: Short lairage is only practiced in about 15% of the grainfed beef industry.

- Best fit: Vertically integrated supply chains show the greatest potential due to streamlined cattle delivery. Non-integrated feedlots might adopt SDL for a portion of their abattoir deliveries.

- Logistical considerations: Successful SDL requires careful management of:

- Electronic paperwork (National Vendor Declarations)

- Transport scheduling

- Communication between feedlots and abattoirs (cattle fitness and vet certificates)

- Ante-mortem inspection scheduling

- Pre-slaughter cattle cleanliness to minimize washing at the abattoir

Further Research:

- Ongoing research will explore SDL in different cattle types (domestic, short-fed export, long-fed export) and under winter/spring conditions.

- Additional research will be needed to confirm effects on grass-fed cattle across various regions in Australia.

Resources:

- Full Report: B.FLT.4017: The effect of lairage duration on carcass quality, yield and microbiological status (MLA website)

- MLA Feedlot Research & Development: https://www.mla.com.au/research-and-development/feedlot/

- National Vendor Declarations: https://www.integritysystems.com.au/on-farm-assurance/national-vendor-declaration-nvd/

- MLA’s Fit to Load Guide: https://www.mla.com.au/

This research suggests that short lairage offers a win-win situation for the Australian grainfed beef industry, enhancing productivity, animal welfare, and potentially contributing to environmental sustainability.

Designing a modern cattle lairage requires careful consideration of several key factors. Immenso, a reputed supplier specializing in slaughterhouse equipment within Bangladesh, can be a valuable resource for this process. They can connect you with reliable construction services and offer insights into the latest technologies and best practices for cost-effective lairage construction.

Here are some key design elements to prioritize:

- Space Allocation: Ensure sufficient space per animal to prevent overcrowding, a significant stress factor. Separate holding pens for different groups of animals are also crucial to minimize disease transmission.

- Environmental Control: Proper ventilation is essential for maintaining air quality and preventing heat stress. Exhaust fans can help manage moisture and odors, while controlled lighting minimizes stress on the animals.

Focusing on Animal Welfare

Beyond efficiency, animal welfare is paramount. Opt for non-slip flooring to prevent injuries and ensure easy cleaning and disinfection for optimal hygiene. Clean, fresh water is vital for animal health, and providing automatic or manual drinkers with adequate access points prevents overcrowding.

Additional Considerations for a Modern Lairage

Biosecurity is critical. Implementing strict hygiene protocols, limiting access to authorized personnel, and utilizing disinfection mats at entry and exit points can significantly reduce the risk of disease outbreaks.

Remember, stress reduction is key. Minimize loud noises, sudden movements, and overcrowding throughout the lairage. Maintaining a comfortable temperature prevents heat stress or hypothermia. Additionally, have a plan in place for emergency situations and conduct regular inspections to ensure optimal functionality and animal safety.

By incorporating these considerations and partnering with reliable suppliers like Immenso, you can create a modern cattle lairage that prioritizes both animal welfare and operational efficiency in your slaughterhouse.