In the cattle slaughtering industry, the hock cutter is a vital piece of equipment designed specifically for cutting through cattle hocks efficiently. This tool not only speeds up the process but also enhances the safety and accuracy of meat processing. Here’s a comprehensive guide on hock cutters for cattle slaughterhouse operations, covering product details, applications, maintenance tips, and top brands. If you’re involved in meat processing, a high-quality hock cutter is an investment worth considering.

Product Description of Hock cutters

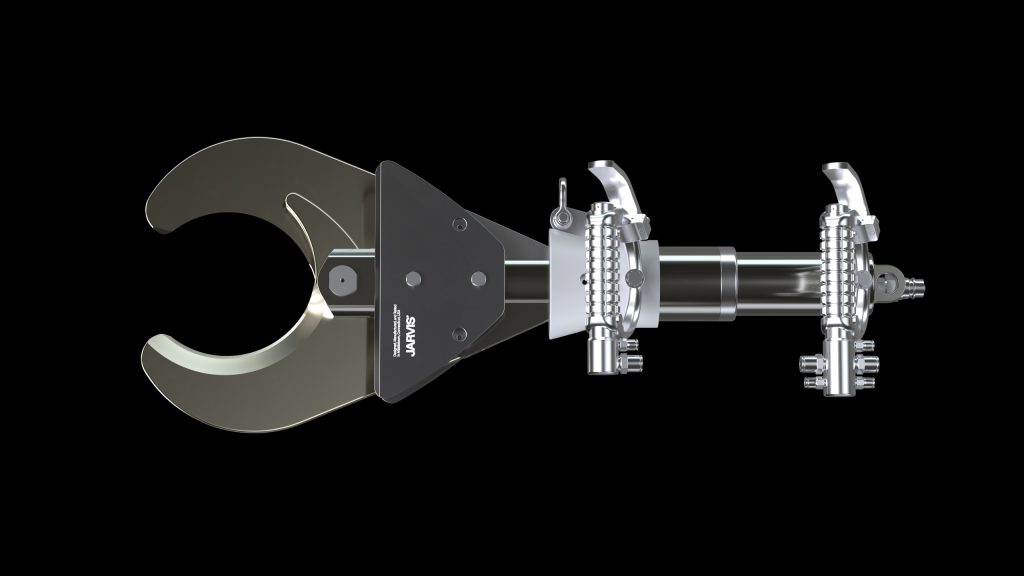

A hock cutter is a specialized tool designed to remove the hocks of cattle in a slaughterhouse setting. Made with durable and corrosion-resistant materials, the hock cutter is typically a hydraulic or pneumatic device that provides powerful and precise cuts through cattle joints. Equipped with ergonomic handles, it ensures comfortable use and minimizes operator fatigue, making it ideal for high-volume processing facilities.

Key Features:

- High-quality stainless steel or other rust-resistant materials

- Powerful hydraulic or pneumatic operation

- Ergonomically designed handles for safe, comfortable use

- Precision blades that minimize damage to surrounding meat

Application of Use

In slaughterhouses, hock cutters are primarily used to remove the hock (the joint between the lower leg and the foot) of cattle after slaughter. This process is an essential part of cattle dressing and ensures that the carcass is prepared properly for further processing. The hock cutter allows operators to quickly and efficiently detach the hock, which reduces labor time and increases productivity on the slaughter line.

The tool is particularly useful in high-throughput slaughterhouses where speed and precision are crucial for maintaining efficiency and meat quality.

Advantages of Using Hock Cutters in Slaughterhouses:

- Speed: Quick removal of hocks increases processing speed.

- Safety: Reduces the risk of manual handling injuries.

- Consistency: Ensures uniform cuts across all carcasses, leading to a better-quality product.

Maintenance Guide of Hock cutters

Proper maintenance of your hock cutter is essential to extend its lifespan and ensure consistent performance. Regular inspections and cleaning will help avoid breakdowns and improve overall productivity.

Maintenance Tips for Hock Cutters:

- Daily Cleaning: After each use, clean the hock cutter with warm water and a mild detergent. This prevents buildup of blood and tissue, which can lead to rust and contamination.

- Lubrication: Apply lubricant to moving parts regularly to ensure smooth operation. Use food-grade lubricants to prevent contamination.

- Inspection: Check for signs of wear on the blades, handles, and hydraulic or pneumatic systems. Replace or repair worn components immediately.

- Sharpening the Blades: Regularly sharpen or replace the blades to maintain cutting efficiency.

- Calibration and Testing: Test the tool periodically to ensure it’s operating at optimal pressure (for pneumatic or hydraulic hock cutters).

Safety Note: Always disconnect the cutter from power sources before performing maintenance.

Popular Brands for Hock cutters

Several brands offer high-quality hock cutters designed for the rigorous demands of slaughterhouses. Below are some of the leading brands trusted in the meat processing industry:

- Jarvis Products Corporation: Known for its durable and efficient hock cutters, Jarvis offers tools that are designed to handle large-scale meat processing tasks. Jarvis Products is a highly recommended choice for slaughterhouses.

- Bettcher Industries: Another reputable name, providing robust hock cutters with ergonomic designs to ensure operator comfort during prolonged use.

- Freund Corporation: A trusted name in the industry, known for its innovative slaughterhouse tools and commitment to high standards of hygiene and safety.

Conclusion

A reliable hock cutter is an indispensable tool in any cattle slaughterhouse, ensuring efficiency, safety, and consistency in meat processing. By choosing a high-quality brand, performing regular maintenance, and ensuring safe operation, you can maximize the cutter’s lifespan and improve productivity on the slaughter line. Whether you’re upgrading your current equipment or outfitting a new facility, a hock cutter can significantly enhance operational efficiency.