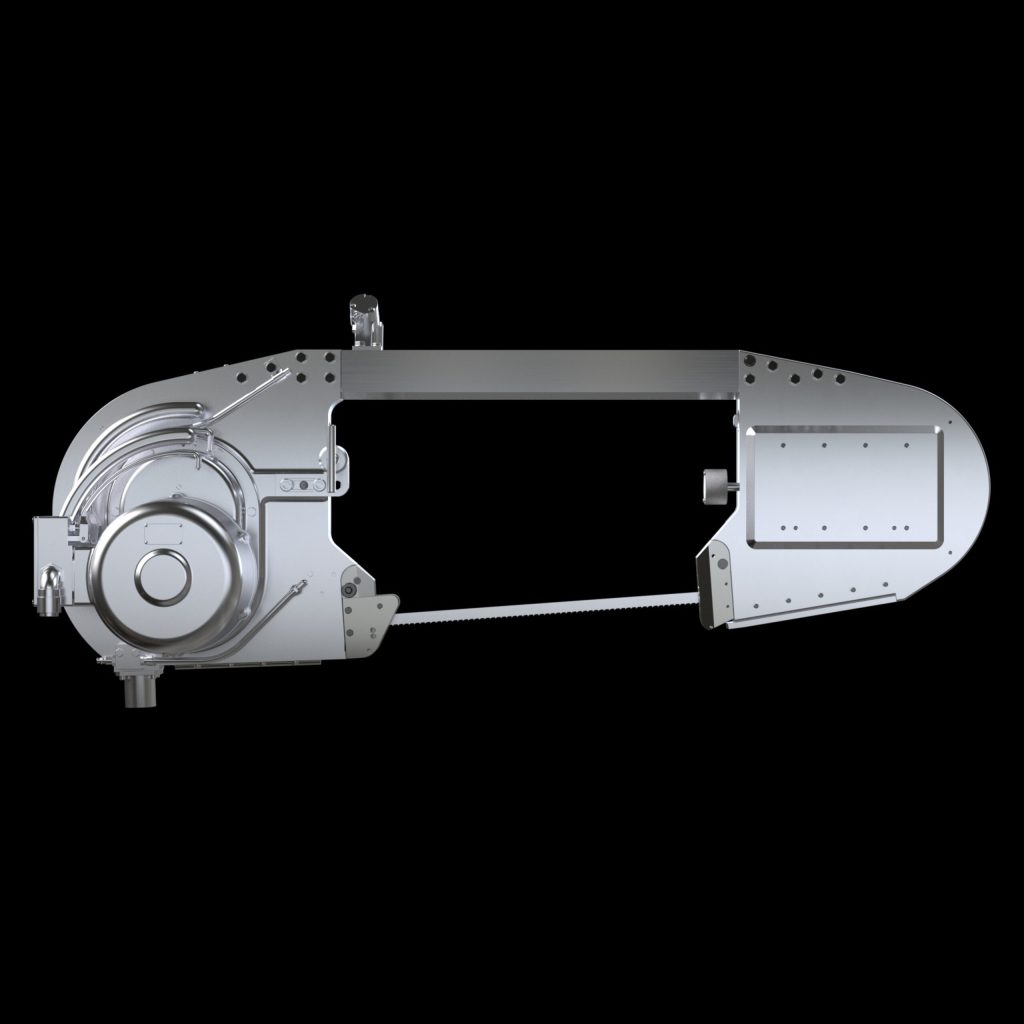

Splitting saw Jarvis BUSTER 5 Electric

Technical Specifications

Motor Power: 2500 W (3.3 hp) and 3730 W (5 hp)

Operating Voltage: 460 / 230 V, 3 phase, 60 Hz (other voltages and 50 Hz available)

Capacity: 180 head per hour

Control Handles: Electric Dual Anti-Tie Down

Distance between Guides: 502 mm (19.75 in)

Blade Length: 3226 mm (127 in)

Overall Length: 1448 mm (57 in)

Drive Wheel Speed: 530 rpm

Vibration (less than): 0.6 m / sec² (115 dB)

Weight: 88.9 kg (196 lbs)

Splitting saw slaughterhouse machines are indispensable for efficient cattle processing in modern meat production facilities. These machines enhance productivity, ensure precision, and maintain the hygiene standards crucial for producing high-quality meat products.

Product Description: Splitting Saw Slaughterhouse

A splitting saw slaughterhouse machine is a specialized piece of equipment designed to cut cattle carcasses into equal halves along the spine. Its robust build, sharp blades, and ergonomic design make it suitable for high-volume operations. Most models feature safety enhancements to prevent accidents, making them both efficient and secure to use.

Application of Splitting Saw Slaughterhouse

The splitting saw is typically used in the final stages of cattle processing, where the carcass is halved for further handling and packaging. It plays a crucial role in:

- Meat Quality Assurance: Ensuring precise cuts for consistent meat quality.

- Hygiene Standards: Reducing the risk of contamination with clean and controlled cuts.

- Operational Efficiency: Speeding up the splitting process, particularly in facilities with high cattle throughput.

Maintenance Guide for Splitting Saw Slaughterhouse

To keep the machine in top condition, follow these maintenance tips:

- Daily Cleaning: Clean blades and handles after every use to avoid buildup of residue.

- Lubrication: Regularly lubricate moving parts to prevent rust and ensure smooth operation.

- Blade Sharpening/Replacement: Inspect blades for dullness and replace as needed.

- Safety Inspections: Check safety guards and other protective features routinely.

Popular Brands for Splitting Saw Slaughterhouse

Several renowned manufacturers supply high-quality splitting saw slaughterhouse machines. These include:

- Jarvis Products: Known for durable and efficient meat processing equipment.

- Immenso.com.bd: A trusted supplier in Bangladesh, offering top-tier splitting saw machines.

Explore their product range here:

Splitting Saw Machine – Immenso.

Benefits of Using a Splitting Saw Slaughterhouse

- Precision: Guarantees accurate and uniform cuts for better product presentation.

- Speed: Accelerates processing time, allowing higher throughput.

- Safety: Modern models come equipped with advanced safety features, reducing the risk of workplace injuries.

- Durability: Built to handle heavy-duty usage in slaughterhouses.

Why Invest in a Splitting Saw Slaughterhouse?

In Bangladesh, where the meat processing industry is growing rapidly, investing in efficient equipment like a splitting saw slaughterhouse machine is essential. It not only boosts productivity but also ensures compliance with global meat processing standards. Companies like Immenso.com.bd and Mycart.com.bd lead the market in providing reliable equipment tailored to the needs of local slaughterhouses.

splitting saw slaughterhouse machines are available in both electric and hydraulic versions. Each type offers specific advantages depending on the operational needs:

Electric Splitting Saws

- Advantages: Lightweight, easier to maintain, and generally more cost-effective.

- Usage: Ideal for smaller-scale operations or facilities with reliable power sources.

- Limitations: May face power efficiency issues in regions with frequent electricity fluctuations.

Hydraulic Splitting Saws

- Advantages: Higher power output, more robust for heavy-duty operations, and suitable for processing larger cattle volumes.

- Usage: Preferred for industrial-scale slaughterhouses with high throughput.

- Limitations: Requires hydraulic systems, which can increase initial setup and maintenance costs.

Many suppliers, including Immenso.com.bd and Mycart.com.bd, offer both options, ensuring you can select the model that best fits your facility’s needs.

A splitting saw for slaughterhouses works by efficiently cutting the carcass of cattle into two symmetrical halves along the spinal column. This step is crucial for processing and inspection in meat production. Here’s how it works:

1. Positioning the Carcass

- The carcass is suspended on a rail or hoist system, ensuring it remains steady during the splitting process.

- Operators ensure proper alignment to prevent uneven cuts.

2. Initiating the Splitting Saw

- The splitting saw, whether electric or hydraulic, is activated.

- The operator grips the machine using ergonomic handles designed for stability and precision.

3. Guiding the Saw Along the Spinal Column

- The blade or chain of the splitting saw is positioned at the top of the spine.

- The operator moves the saw steadily downwards, splitting the carcass into two halves with precision.

- Built-in guides on the saw ensure straight and uniform cuts, enhancing meat quality and presentation.

4. Safety Features in Action

- Safety shields and guards protect the operator from blade exposure.

- Automatic brake systems halt the blade when not in use, reducing risks.

5. Post-Operation Steps

- After splitting, the machine is turned off, and the blade is cleaned to remove residue.

- The carcass halves are moved for further processing, inspection, or packaging.

This process ensures quick, clean, and efficient splitting, maintaining hygiene and operational standards in the slaughterhouse.

Internal Functionality of a Splitting Saw Slaughterhouse

The splitting saw slaughterhouse operates using a combination of mechanical and electrical or hydraulic components, all working together to ensure efficient and precise splitting of cattle carcasses. Here’s a breakdown of how this machine functions internally:

- Motor (Electric or Hydraulic Drive)

- The motor is the powerhouse of the machine, converting electrical or hydraulic energy into mechanical motion.

- Electric Motor: Powers the blade using electricity, suitable for facilities with stable power supplies.

- Hydraulic Motor: Offers higher torque and is ideal for heavy-duty operations, ensuring smooth and consistent performance.

- Cutting Blade or Chain

- A high-strength steel blade or chain is mounted on the saw to handle the tough task of cutting through bones and tissues.

- The blade operates at high speeds, driven by the motor, to ensure precise and quick cuts.

- Special coatings on the blade reduce wear and tear and improve hygiene by resisting bacterial growth.

- Blade Guide System

- A guide rail or support structure ensures that the blade remains aligned along the carcass’s spinal column.

- This system minimizes deviation, improving accuracy and reducing the risk of errors during splitting.

- Cooling and Lubrication System

- Many splitting saws include an integrated cooling and lubrication system to prevent the blade from overheating during prolonged operations.

- This system also helps maintain blade sharpness and reduces friction, extending the equipment’s lifespan.

- Safety Features

- Automatic blade guards retract only during cutting, protecting operators from accidental contact.

- Emergency stop buttons and pressure-sensitive controls enhance operational safety.

- Exhaust and Debris Management

- The machine is equipped with a mechanism to expel bone dust and meat debris generated during the cutting process, maintaining a clean working environment.

By combining these components, the splitting saw slaughterhouse ensures efficient, precise, and hygienic carcass processing, making it indispensable in modern meat production facilities.

Users of Splitting Saw Slaughterhouse Machines in Bangladesh

The splitting saw slaughterhouse machine is essential for modern meat processing, and its users span across various sectors in Bangladesh, including:

- Bengal Meat Processing Industries Ltd.

- As a pioneer in processed meat production in Bangladesh, Bengal Meat utilizes splitting saws for precision carcass splitting, ensuring premium quality and hygiene standards for their products.

- Dutch Dairy Private Limited

- Renowned for providing advanced slaughterhouse and meat processing equipment, Dutch Dairy supports their clients with high-performance splitting saws to meet international quality benchmarks.

- Large Slaughterhouses

- Government and privately operated slaughterhouses, such as the Dhaka City Corporation’s Hazaribagh and Kaptan Bazar slaughter projects, rely on splitting saws to handle high-capacity processing while maintaining efficiency and safety.

- Meat Exporters

- Companies exporting meat products use splitting saws to comply with international standards, ensuring uniformity and precision in carcass processing.

- Supermarkets with In-House Processing

- Large supermarket chains with dedicated meat processing units use splitting saws to produce bone-in meat cuts with consistent quality.

- Specialized Meat Processors

- Businesses focusing on premium cuts or bone-in products use splitting saws for their reliability and efficiency in achieving precise results.

- Academic and Research Institutions

- Veterinary universities and training centers employ splitting saws for educational purposes and research in meat processing techniques.

These machines enable streamlined operations, enhance production standards, and align with food safety regulations, making them indispensable for users in Bangladesh’s evolving meat industry.

In the fast-paced world of meat processing, efficiency is key. Splitting saws play a crucial role in this process, allowing for the quick and precise division of carcasses into halves. Here at Immenso (links to products: splitting saw EFA-SB-327-E: https://immenso.com.bd/product/splitting-saw-efa-sb-327-e/, Jarvis Buster-5 Electric: https://immenso.com.bd/product/splitting-saw-jarvis-buster-5-electric/, Brisket Saw: https://immenso.com.bd/product/brisket-saw-slaughterhouse/, Splitter Band Saw WFA-FC-ST08-D: https://immenso.com.bd/product/splitter-band-saw-wfa-fc-st08-d/), we offer a variety of splitting saws to suit your specific needs. Whether you require a heavy-duty electric saw like the Jarvis Buster-5 or a more compact option like the EFA-SB-327-E, we have the right tool to keep your operation running smoothly.

Additional information

| Brand | Jarvis |

|---|---|

| Type | Splitting Saw |

General Inquiries

There are no inquiries yet.

Reviews

There are no reviews yet.